Industrial drone solutions combine data acquisition, inspections, and high-altitude cleaning across construction, energy, agriculture, and more—using LiDAR, SLAM, thermal imaging, and tethered pressure-washing systems.

Introduction to Industrial Drone Solutions

A decade ago, drones were toys for hobbyists and tools for the military. Today, they are mission-critical platforms that not only capture data but also perform work in the field—from mapping and inspections to cleaning building facades and infrastructure.

Modern industrial drone solutions combine data acquisition, asset inspection, and high-altitude cleaning, giving organizations a safer, faster, and more cost-effective way to manage the physical world. Instead of sending people onto roofs, scaffolding, or into confined spaces, companies deploy drones, SLAM LiDAR rigs, and tethered cleaning systems to handle both sensing and surface treatment.

This guide explains how industrial drones are used for 3D mapping, inspections, and high-altitude pressure washing—and how these capabilities fit together into a single, modern workflow for asset management and maintenance.

The Evolution of Industrial Drone Technology

Early commercial drones were essentially flying cameras with limited range and basic imaging. Today’s industrial platforms integrate high-resolution RGB cameras, LiDAR scanners, FLIR thermal imagers, multispectral sensors, GNSS/RTK positioning, and AI-driven analytics. This evolution has transformed drones into full-fledged data-collection and work-execution systems.

At the same time, ground-based and mobile systems—like handheld and backpack SLAM LiDAR scanners—have matured, allowing operators to map complex interiors, tunnels, and GPS-denied areas with centimeter-level accuracy. Tethered drone cleaning systems now add a third dimension: drones that don’t just inspect, but also clean and treat surfaces at height.

The result is a unified toolbox for seeing, measuring, and maintaining critical assets without exposing people to unnecessary risk.

Key Benefits: Cost, Safety, and Data Quality

Cost Savings and Operational Efficiency

Traditional inspections rely on scaffolding, cranes, rope access, or helicopters—all of which are expensive, slow, and labor-intensive. Drones change the math:

- A single drone can inspect rooftops, tanks, towers, and lines in hours instead of days, cutting inspection labor and equipment costs by 40–70% in many scenarios.

- LiDAR- and photogrammetry-based surveys can capture large sites in one or two flights instead of weeks of ground crews, dramatically reducing survey timelines.

- Tethered cleaning systems cover large facade areas quickly, reducing the need for rope-access crews and minimizing downtime for building occupants.

For many organizations, the payback period on a well-designed drone program is measured in months, not years.

Improved Safety in Hazardous Environments

Safety is one of the strongest arguments for industrial drones. Instead of putting people in harm’s way, you send a unmanned system first:

- Inspections of high-voltage lines, flare stacks, chimneys, or tanks can be done without exposing crews to falls, arc flash, or confined-space hazards.

- High-altitude cleaning drones eliminate many scenarios where workers would otherwise hang from ropes or ride in boom lifts at height.

- SLAM-based mobile mapping allows technicians to walk through complex facilities without climbing scaffolds just to take measurements.

Reducing exposure to fall hazards, energized equipment, and confined spaces doesn’t just protect people—it also cuts insurance costs and avoids costly incident investigations.

Better Data, Faster Decisions

Industrial drones and SLAM systems deliver richer, more consistent data than most manual methods:

- High-resolution RGB and zoom cameras document the exact condition of assets with repeatable visual records over time.

- LiDAR and SLAM produce dense, survey-grade 3D point clouds that support precise measurements, clash detection, and digital twins.

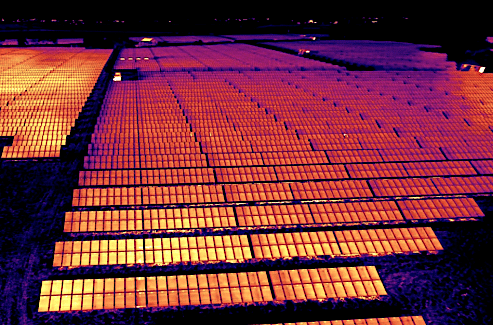

- Thermal (FLIR) and multispectral sensors reveal heat signatures, moisture, and vegetation health that you can’t see with the naked eye.

This combination supports true data-driven maintenance—catching issues early, prioritizing repairs, and verifying that work was done correctly.

Core Services Offered by Industrial Drones

1. Aerial Data Acquisition and 3D Mapping

Industrial drones capture high-resolution imagery, LiDAR, and multispectral data to create detailed maps and 3D models of sites and assets. Using photogrammetry and LiDAR, you can generate:

- Orthomosaic maps for planning and documentation

- Digital terrain and surface models (DTM/DSM) for earthwork and drainage

- Dense 3D point clouds and meshes for engineering, design, and BIM integration

These outputs plug directly into GIS platforms, BIM tools, and CAD workflows, helping teams design projects, quantify volumes, verify as-built conditions, and monitor change over time.

2. Industrial Inspections (Visual, Thermal, and LiDAR)

Drones equipped with RGB, thermal, and LiDAR sensors perform close-range inspections of structures that are hard, expensive, or dangerous to reach with traditional methods.

Typical inspection targets include:

- Rooftops and building envelopes

- Bridges, highways, and rail infrastructure

- Transmission lines, substations, and insulators

- Wind turbines, solar farms, and telecom towers

- Tanks, stacks, flare systems, and industrial plants

High-resolution cameras reveal cracks, corrosion, and alignment issues, while thermal imagers highlight heat anomalies, moisture, and electrical faults. LiDAR adds precise geometry for measuring deformation, clearances, and volumes. AI-powered tools can then scan thousands of images or point-cloud slices to flag potential defects automatically.

3. High-Altitude Cleaning and Surface Treatment

Industrial drones are no longer limited to “looking”; tethered cleaning systems now let them “do” work at height. High-altitude cleaning drones use continuous water and power tethers to deliver high-pressure sprays—often in the 110–160 bar range—with cleaning heights up to 60 meters and several hours of continuous operation.

Typical applications include:

- Building facades and glass curtain walls

- Sound walls along highways

- Industrial tanks and silos

- Wind turbine towers and blades

- Solar arrays and power line insulators

These systems replace or reduce the need for scaffolding, rope access, and boom lifts, cutting labor risks and enabling faster, more consistent cleaning across large surface areas. Some platforms even support spray painting and coating, extending their use beyond cleaning into protective maintenance.

Mobile and Walking SLAM LiDAR Mapping

Not every environment can or should be mapped from the air. Plants, campuses, tunnels, utility corridors, and interior spaces often have overhangs, tight clearances, or GPS-denied areas where traditional drone mapping struggles.

Mobile and walking SLAM LiDAR systems solve this by letting technicians “walk and scan” or “drive and scan” while the sensor continuously builds a detailed 3D model in real time. Modern SLAM units can capture hundreds of thousands of points per second at millimeter- to centimeter-level accuracy, often combined with panoramic imagery for colorized point clouds.

This approach is ideal for:

- Indoor as-builts of industrial facilities and commercial buildings

- Tunnels, underground galleries, and utility corridors

- Complex campuses where aerial data needs to be supplemented with interior mapping

Combined with aerial LiDAR or photogrammetry, SLAM-based mobile mapping gives owners a unified inside–outside 3D model of their assets, enabling better planning, clash detection, and documentation without scaffolding or lengthy shutdowns.

Thermal (FLIR), Topographic, Forestry, and Bathymetric LiDAR

Thermal (FLIR) Imaging for Hidden Issues

Forward-Looking Infrared (FLIR) cameras measure tiny temperature differences across surfaces, revealing problems that standard cameras can’t see. In a single flight, thermal drones can:

- Detect moisture intrusion and saturated insulation in flat roofs

- * Identify missing insulation, air leaks, and thermal bridges in building envelopes

- * Spot overheating electrical components, transformers, and connections

- * Highlight failing mechanical and HVAC components across rooftops and yards

Paired with RGB imagery, FLIR data gives facilities and maintenance teams a precise visual map of where to focus repairs before issues become failures.

Topographic LiDAR and Forestry Mapping

Topographic LiDAR uses laser pulses to capture highly accurate 3D models of the ground surface, even in dense vegetation where cameras can only see the canopy. Because LiDAR pulses can return multiple reflections from canopy and ground, you can:

- Generate detailed elevation models for earthwork, grading, and drainage design

- * Map forest structure, canopy height, and biomass for forestry and conservation

- * Measure volumes of stockpiles, landfills, and quarries with survey-grade accuracy

- * Survey rugged or overgrown terrain that is slow or dangerous to traverse on foot

For environmental and forestry projects, repeat LiDAR flights create time-series datasets that help track vegetation changes, erosion, and landform evolution.

Bathymetric LiDAR for Water and Shorelines

Bathymetric LiDAR uses green laser light that can penetrate clear water, capturing separate returns from the water surface and the underwater terrain. Mounted on aircraft or suitable drone platforms, topo-bathymetric systems can:

- Measure water depth and map riverbeds, lakes, reservoirs, and coastal zones

- * Support flood modeling, erosion studies, and coastal engineering

- * Create continuous 3D models of beaches, river corridors, and shorelines that link land and water data

In combination with topographic LiDAR, bathymetric data gives engineers and environmental teams a complete picture of how land and water interact along critical corridors.

Industries Leveraging These Capabilities

Construction and Infrastructure

Contractors use drones for topographic surveys, cut/fill analysis, progress monitoring, QA/QC, and final documentation, often cutting survey and inspection time by 50% or more. High-altitude cleaning drones can then prepare glass and facades before handover, reducing punch-list items for exterior appearance.

Energy and Utilities

Energy companies rely on drones to inspect transmission lines, substations, wind turbines, solar farms, and pipelines with a combination of RGB, thermal, and LiDAR sensors. Tethered cleaning systems are increasingly used to wash insulators, towers, and solar panels, improving performance without taking assets offline for long periods.

Agriculture and Forestry

In agriculture, drones and multispectral sensors support precision farming by monitoring crop health, irrigation, and nutrient stress. In forestry, LiDAR and imagery help map canopy structure, biomass, and terrain, supporting sustainable harvest planning and environmental monitoring.

Mining and Industrial Sites

Mines and industrial sites use drones for stockpile volumetrics, haul road inspections, slope monitoring, and facility as-builts, often replacing risky ground-based surveys. SLAM-based mobile mapping is particularly useful in underground workings and complex plants where GPS is unavailable.

How These Capabilities Work Together in the Real World

In practice, most projects don’t use just one tool—they combine several of these capabilities in a single workflow:

- A construction site might start with LiDAR or photogrammetry topo surveys, use weekly RGB/thermal flights for progress and quality checks, and finish with high-altitude cleaning of glass or precast before handover.

- * A utility or industrial plant might create an indoor as-built with SLAM LiDAR, schedule periodic thermal/visual inspections of roofs, lines, or tanks, and use tethered cleaning drones to remove contamination from facades, tanks, or sound walls without scaffolding.

- * An environmental or forestry project might blend topographic and bathymetric LiDAR to capture river corridors and floodplains, while using repeat aerial surveys to monitor erosion, vegetation change, and biomass over time.

The common thread is simple: instead of sending people into risky or time-consuming situations, you send sensors and unmanned systems first—then act on clean, objective data.

Conclusion

Industrial drone solutions now span far more than aerial photography. With LiDAR, SLAM, FLIR thermal imaging, multispectral sensors, and tethered cleaning systems, you can map, inspect, and clean critical assets across industries while reducing cost and risk.

Whether the job is capturing a millimeter-accurate 3D model, finding a hidden leak, or washing a 60‑meter facade, drones and mobile mapping systems give you a safer way to see and service your assets—on the ground, at height, and even below the waterline.